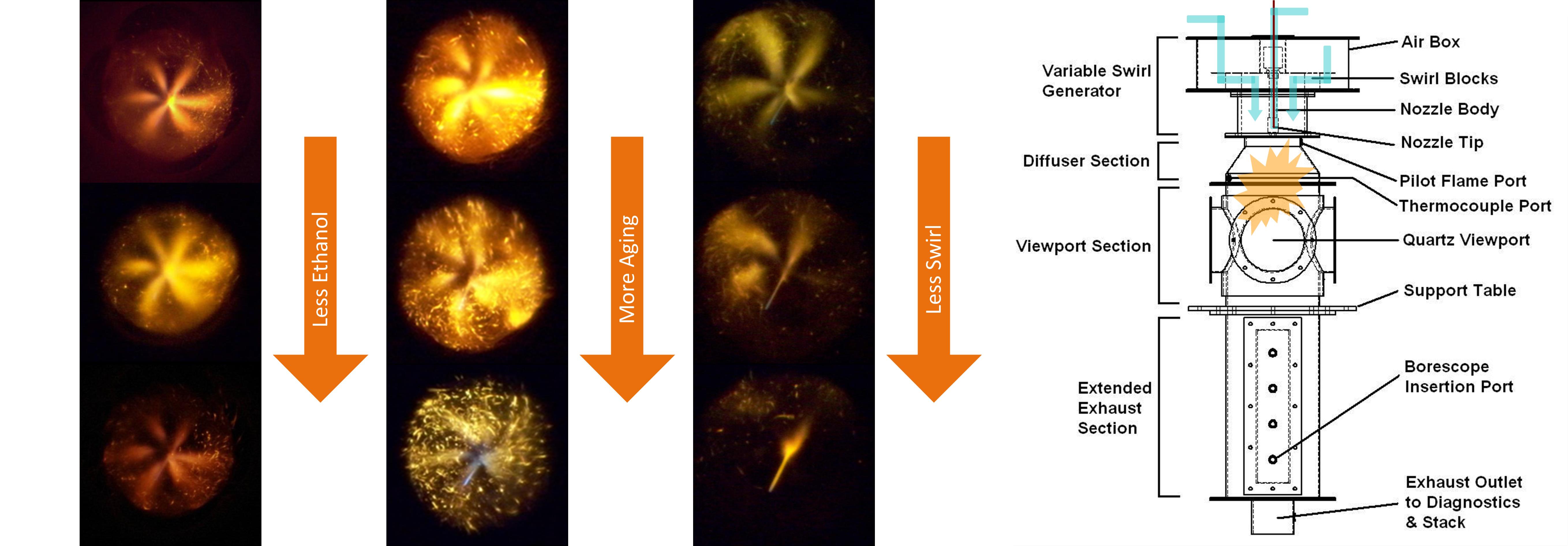

From left to right: the appearance of the swirl stabilized bio-oil flame with varying ethanol content, fuel aging, and swirl, a schematic of the bio-oil burner

Bio-Oil Research

Pyrolysis Oil, or bio-oil, is an alternative fuel derived from the fast pyrolysis of biomass. Bio-oil has the potential to replace heavy fuel oil in power and heating applications. The overall goal of our bio-oil research is to overcome the obstacles involved with its combustion. Composition of the bio-oil varies with different feed stocks, but because it comes from biomass, typically the fuel contains high amounts of ash and water. With high water, combustion can be difficult to maintain and with high ash, small components can get clogged. Our current projects include burning bio-oil with natural gas in a burner to observe the improvement in combustion and running a diesel engine on bio-oil.

Bio-Oil Burner

In order to better understand how the combustion of bio-oil can be improved to be viable for industrial use, we are co-firing it with natural gas. The addition of natural gas adds a volatile component that is typically missing from pure bio-oil. In order to compare flame quality, the power output is kept constant at 10kW, and the natural gas, mixed with nitrogen, replaces the atomizing air that would typically be used. In order to evaluate the combustion quality, the burner is equipped with many temperature measurement ports, optical access, an oxygen sensor, FID (to measure unburnt hydrocarbons) and an FTIR (to measure exhaust composition). With these sensors and the ability to control the concentration of natural gas added, we have the ability to evaluate the combustion quality of a wide array of fuelling conditions.