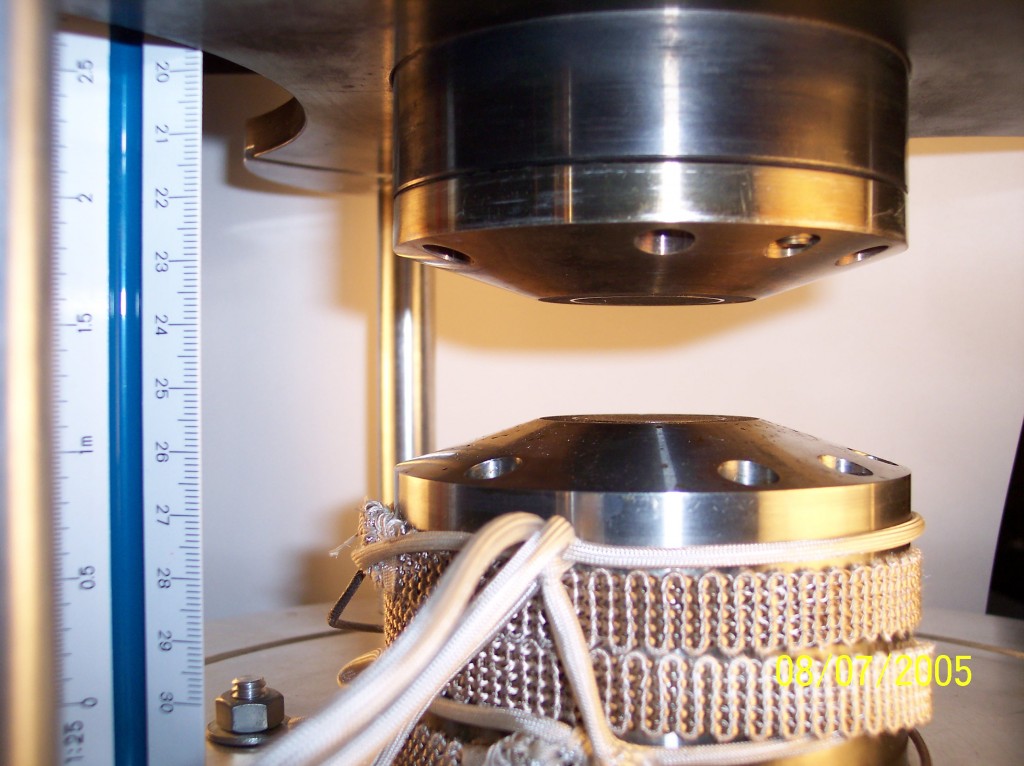

The experimental setup requires two identical McKenna flat flame burners that are coaxially mounted 20 mm apart and are facing each other. The fuel stream is fed through the bottom port, while the oxidizer stream is fed through the top port. Each burner port consists of a stainless steel housing that encloses a porous sintered bronze matrix. The porous matrix is divided into inner and outer coaxial cylinders with diameters of 25.4 mm and 38.1 mm, respectively. The inner cylinder directs the fuel or oxidizer stream and the outer cylinder can be used to create a nitrogen shroud around the flame to minimize external flow disturbances. The annulus’ shrouding feature was not used in this study. The porous plugs

ensure that the gases have a uniform laminar flow and flat velocity profile at the port’s surface.

A custom built aluminum holder provides support for the two burners and a clear quartz shroud with a diameter of 22 cm protects the flame from airflow disturbances from the surrounding environment. The unit is mounted on a translation stage, which moves along the vertical axis with the rotation of a micrometer knob. This stage allows for the vertical profile of the flame to be analyzed for temperature and species concentrations between the two burner ports. Combustion gases from the burner are vented through a canopy hood, which is vented to the laboratory fume hood The temperature of the gases flowing through the ports was controlled by circulating hot air through the porous plugs packed between two coaxial cylinders.